Autonomous Logistics Intelligence: The Future of Modern Fulfillment

Discover how autonomous logistics intelligence is revolutionizing fulfillment, from dynamic routing and automated warehousing to enhanced visibility and cost reduction at each point of delivery

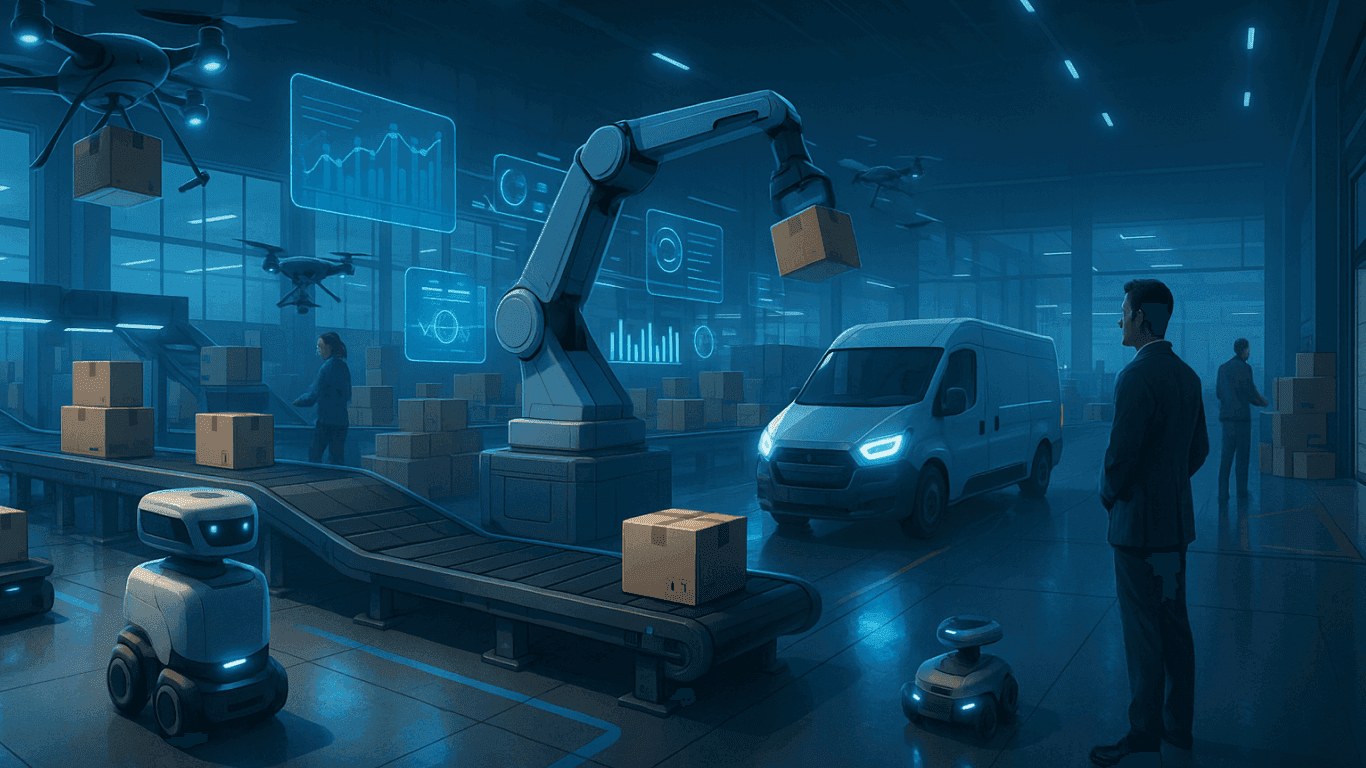

How Autonomous Logistics Intelligence is Redefining Modern Fulfillment

In the rapidly evolving global marketplace, the logistics and fulfillment sector is experiencing a significant transformation fueled by advances in technology. Leading this change is autonomous logistics intelligence, a fusion of artificial intelligence (AI), robotics, self-operating vehicles, and Internet of Things (IoT) innovations that work together to automate, enhance, and fundamentally revolutionize the processes of fulfilling and delivering goods.

This article delves into how autonomous logistics intelligence is reshaping modern fulfillment practices, highlighting its major advantages, challenges, and the future direction of an industry swiftly progressing toward intelligent, autonomous, and self-regulating supply chains.

Autonomous logistics intelligence involves the use of smart systems capable of functioning with minimal human oversight to oversee and enhance logistics operations. Data collection, machine learning, automated decision-making across facilities, transportation fleets and delivery channels are included in this.

Rather than depending on manual labor and fixed procedures, autonomous logistics intelligence leverages:

- AI-powered analytics to analyze real-time data streams,

- Robotics and automation to handle physical goods,

- Autonomous transport options like drones and self-driving trucks,

- IoT technology to continuously monitor and connect all supply chain components.

Combined, these advanced technologies build a responsive and scalable logistics network that operates more quickly, efficiently, and with fewer errors.

1. Advanced Automation and Increased Operational Efficiency

Traditionally, warehouses and fulfillment centers have depended heavily on human labor to carry out tasks such as picking, packing, sorting, and loading orders. Autonomous logistics intelligence revolutionizes these environments by deploying robots and automated systems that function continuously without interruption.

Robotic fulfillment: Autonomous mobile robots (AMRs) move throughout warehouse floors to collect products and deliver them to humans or packing stations. This automation significantly cuts down order processing durations and minimizes errors caused by worker fatigue.

Automated sorting and packaging: AI-powered vision technologies simplify quality inspections and sorting processes, ensuring accuracy and proper preparation of shipments.

Round-the-clock operations: Unlike conventional methods, these autonomous systems operate non-stop, boosting throughput and accommodating the rising demands of ecommerce.

Together, these advances streamline workflows by cutting down manual handling, shortening processing times, and speeding up order fulfillment cycles.

2. Real-Time, Data-Driven Decision-Making

Autonomous Logistics intelligence has evolved in utilizing current data streams to get quicker and more effective decisions.

By leveraging predictive analytics: AI evaluates past and real-time data to anticipate demand surges, enabling prompt inventory restocking and more efficient resource management.

Dynamic routing: Autonomous delivery fleets and fleet management platforms continuously assess traffic conditions, weather, and road information to choose the most efficient paths, reducing fuel consumption and delivery times.

End-to-end supply chain visibility: Continuous IoT sensor updates allow precise tracking of shipments, lowering loss rates, enhancing transparency, and enabling quick responses to disruptions.

This data-focused methodology enables fulfillment centers to shift from reactive responses to proactive management, greatly improving reliability and speed.

3. Cost Efficiency and Resource Maximization

Autonomous logistics intelligence provides in automating repetitive tasks, streamline material flows and maximizes the use of assets.

Cutting labor costs: Labour charge high payments during high-demand times so by assigning those repetitive duties to robots, companies can save their money on spending in hiring human staff.

Reduced fuel and transport costs: Intelligent route planning minimizes unnecessary mileage, saving fuel and decreasing wear and tear on vehicles.

Optimized warehouse utilization: AI-driven analytics rearrange storage layouts and optimize inventory placement to make the best use of space and reduce travel distances within the warehouse.

These improvements create leaner, more cost-effective operations that increase profitability and support scalable growth.

4. Enhanced Safety and Risk Mitigation

Enhancing safety is a vital benefit brought by autonomous logistics intelligence systems:

Reduced human mistakes: AI-controlled autonomous robots and vehicles help lower the chances of accidents caused by fatigue or errors

Real-time anomaly detection and cybersecurity: AI continuously monitors equipment health, shipment condition, and potential security threats to proactively address vulnerabilities before they escalate.

Regulatory Appliances: Automated monitoring and reporting support compliance with safety standards and transportation regulations, reducing legal risk and promoting reliable operations.

Together, these aspects foster safer work environments and strengthen the security of logistics operations.

5. Elevated Customer Satisfaction

Ultimately, improvements driven by autonomous logistics intelligence lead to better experiences for customers:

Faster delivery: Automation accelerates order handling and shipping, enabling rapid delivery services such as same-day or even same-hour fulfillment.

Reliable and accurate orders: Including technology like AI guarantee that consumers get the correct items on time that helps in reducing returns and complaints.

Real-time updates: Constant tracking and communication keep customers informed about their order status, enhancing transparency and trust.

Meeting today’s consumer demands for speed and convenience gives companies a competitive advantage in the market.

6. Greater Supply Chain Resilience and Scalability

In a world where disruptions such as pandemics, geopolitical upheavals, or natural disasters occur frequently, supply chains must remain flexible and robust. Autonomous logistics intelligence contributes to resilience by:

Rapid adaptation: AI systems detect bottlenecks and recommend alternative actions instantly, rerouting inventory or transportation as necessary.

Scalable capacity: Automated processes allow the operation to smoothly expand or contract without requiring extensive workforce retraining.

Seamless integration: Connecting suppliers, warehouses, and transportation within a single intelligent platform ensures flexibility and coordinated responses.

This resilience guarantees continuous fulfillment performance even during uncertain times.

Despite its transformative potential, adopting autonomous logistics intelligence comes with obstacles:

Significant capital expenditure: Deploying AI, robotics, and self-driving vehicles demands a large initial investment, along with ongoing maintenance costs.

Regulatory complexity: Laws governing autonomous delivery technologies differ by region and are continuously evolving, potentially slowing deployment.

Cybersecurity concerns: Increased interconnectivity creates new risks that must be managed with strong security protocols.

Workforce transformation: Changing job responsibilities necessitate well-planned retraining initiatives and careful management of organizational change to effectively support employees through the transition.

Effective implementation typically requires running pilot programs, involving key stakeholders, gradually adopting technologies, and encouraging ongoing innovation.

The future of autonomous logistics intelligence is moving toward more comprehensive integration and increased complexity. Key developments to watch include:

Completely autonomous delivery fleets: As regulations advance, self-driving trucks and drones will become common for last-mile delivery services.

AI-driven autonomous warehouses: Fulfillment centers will be largely managed by AI systems that coordinate robots, conveyor belts, and human overseers seamlessly.

Blockchain-powered supply chains: The use of immutable ledgers will boost transparency and trust alongside autonomous logistics operations.

Emphasis on sustainability: Autonomous systems will optimize processes to lower carbon emissions and promote efficient resource utilization.

Early adopters of these cutting-edge technologies are positioned to transform their competitive edge through enhanced speed, cost savings, and improved customer loyalty.

Autonomous logistics intelligence has moved beyond theory to become a practical force transforming the way modern fulfillment functions. By integrating AI, robotics, autonomous vehicles, and IoT technologies, it establishes an agile, smart supply chain that operates faster, more safely, and cost-efficiently while remaining highly flexible. CRM in logistics is quite helpful and in many ways like real-time tracking, data-driven decision making and gives you the seamless communication. Alongside this it gives you operational efficiency and enhances the customer services. This innovation enables unprecedented operational performance and elevates customer experiences, providing a crucial competitive edge in today’s demanding market. Organizations that proactively adopt and develop autonomous logistics intelligence will lead the evolution of future supply chains.

More blogs

No More blogs